◆ Fast, safe and repetative connection

◆ High grade material

◆ Time and cost saving

◆ No hand or wrench tightening required

◆ No damage to test pieces

![]() LANGAN® Quick Connector Catalog

LANGAN® Quick Connector Catalog

![]() LANGAN® LA650 Quick Connector Selection Guide

LANGAN® LA650 Quick Connector Selection Guide

| Technical data | |

| Product name | LANGAN® LA650 conectores entre roscas jaw locking high pressure quick connector for leak test |

| Connection type | Components with a bead, rim, collar, flange, stub or male/external thread |

| Operation pressure (PS) | Port B: vacuum up to Max. 350 bar |

| Media | Oil, air and water |

| Leak rate | 1*10-3 mbar.l/s(10-4 Pa.m3/s) |

| Temperature range | +5℃~+80℃ |

| Material of construction | Corrosion resistant stainless steel |

| Sealing material | NBR for main seals, other material available on request |

1. Specification: The LA650 quick connect fitting, for high pressure vacuum & gas leak test, is applicable for high pressure and function testing of components with a bead, rim, collar, flange, stub and male thread.

In automotive industry, LA650 jaw locking leak test quick connector is also used for testing water line and fuel line of the engine, supply line of the brake system, supply line of the compressor and hose ends.

In engine fuel line test application, a build-in internal shut-off valve is available.

2. Operating instructions:

![]() Please strictly follow the operation steps. Improper operation can cause poor sealing, leakage and risk of connection failure resulting in damage or injury. Do not disconnect the connector while under pressure. Damage or injury may occur.

Please strictly follow the operation steps. Improper operation can cause poor sealing, leakage and risk of connection failure resulting in damage or injury. Do not disconnect the connector while under pressure. Damage or injury may occur.

◆ Grip the connector by sliding sleeve;

◆ Carefully place the connector straight onto the test piece;

◆ Slide the sliding sleeve forward. Make sure the connector is completely placed into place. The connector grips itself to the test piece and achieves a pressure-tight connection;

◆ Introduce the required test pressure to media inlet to start the test process;

◆ At the end of the test process, vent the media line completely. Make sure to depressurize the connector before releasing the connection;

◆ Pull the sliding sleeve backward to disconnect the connector with the test piece.The test process is finished.

3. Application:

LA650 high pressure leak test quick connector is applicable for high pressure and function testing of components with a bead, rim, collar, flange, stub and external thread.

CONNECTS TO:

4. How to order:

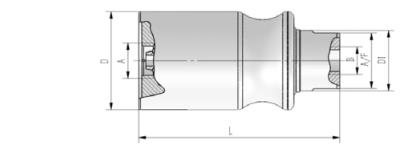

LA650 quick connectors are designed for male threaded components. Normally we need the following information for ordering:

◆ Part numbers ◆ Pressure range

◆ Media/requested leak rate ◆ Temperature range

◆ Space requirement (interference contours, clearance, etc.)

◆ CAD drawing, 3D model of the test piece

★ For detailed part numbers and dimensions, please download ![]() LA650 Quick Connector Selection Guide.

LA650 Quick Connector Selection Guide.

5. How to customize:

Customized quick connectors are designed to a specific client's demand of leak test solutions to perfectly adapt to testing space, various connection ends and surface conditions. Please click and INQUIRE us.