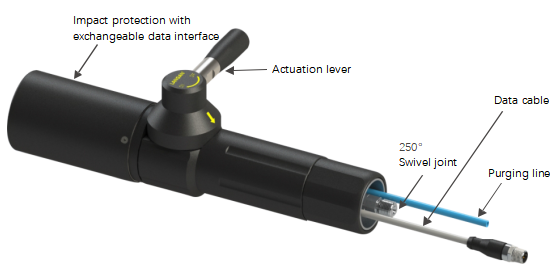

◆ High pressure 70Mpa

◆ Type C hydrogen nozzle as per SAEJ2600: 2015, Article 3.7

◆ Compatible with HR1-70A hydrogen receptacle;

◆ Exchangeable data interface (ENR)

◆ Integrated with Nitrogen purging line

◆ 250° swivel joint for air inlet

◆ Protection agaist impact and cold;

◆ Thermal protection;

◆ Jaw locking mechanism;

◆ Coding for pressure range and gas type

![]() Hydrogen Fueling Components Manual

Hydrogen Fueling Components Manual

![]() HF17-70AND Hydrogen Fueling Nozzle Selection Guide

HF17-70AND Hydrogen Fueling Nozzle Selection Guide

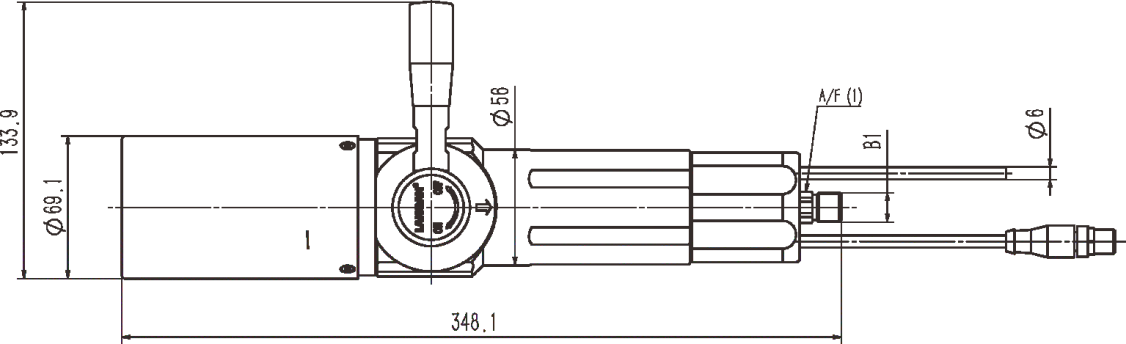

| Technical data | |

| Product name | LANGAN®HF17-70AND 70MPa High Pressure Hydrogen Fueling Nozzle H₂ with Data Interface |

| Nominal bore (DN) | 4mm |

| Pressure range | PN=70MPa / PS=87.5MPa |

| Nozzle type | Type C, according to SAE J2600:2015 and previous respectively; acco. to ISO 17268: 2012 and previous respectively |

| Max. permissible pressure range (not in use) | PS=50MPa |

| Media/Ambient temperature range |

-40∼+85℃ |

| Body material | Corrosion resistant |

| Sealing material | Hydrogen resistant |

| Design | With plastic thermal insulation protection, exchangeable data interface according to SAE J2799., integrated purging tube |

| Weight | about 2.7kg |

| Test and certificate | Fueling nozzle acco. to SAE J2600: 2002, obtained Explosion-proof Certification, infrared data interface acco. to SAE J2799 |

1. Description:

HF17-70AND 70MPa ENR (Enchangeable nozzle receiver) Hydrogen Refueling Nozzle is integrated with exchangeable data interface. It is fitted with a purging tube to flush the nozzle with nitrogen during and after fueling process, which can prevent moisture entering and freezing when fueling with pre-cooled hydrogen. Therefore, fueling nozzle can be easily removed from the fueling receptacle even in the adverse climatic conditions.

2. Safety designs:

◆ Coding of the pressure range and gas type: Removing risk of exceeding the max. permissible pressure and confusion with the natural gas during fueling;

◆ Jaw locking mechanism: Designed specially for the frequent plugging and unplugging of high pressure hydrogen refueling process, providing optimal safety to the operators;

◆ Impact and cold protection: Providing more safety and makes the nozzle more durable in the harsh and difficult refueling environment;

◆ Infrared data interface: The interactive data interface design enables commnunication between the hydrogen fuel cell EV and fueling station. It is capable of sending filling data during refueling via an infrared communication link, which can realize real-time monitoring of the hydrogen refueling.

3. Application:

The hydrogen refueling nozzle is mounted on hydrogen dispenser in the self-service hydrogen fueling station for fast hydrogen fueling.

4. Comparision of LANGAN® Hydrogen Refueling Nozzle:

| Nozzle No. | Nominal Bore (DN) | Pressure PN | Weight | Nozzle type | Data interface | Applicable | Compatible receptable |

| HF16-35A | 8mm | 35MPa | 2.5kg | Type A | Without | Light duty vehicles | HR1-35A |

| HF16-35AD | 8mm | 35MPa | 2.8kg | Type A | With | Light duty vehicles | |

| HF25-35A | 12mm | 35MPa | 4.7kg | Type A | Without | Buses&turcks | HR5-35A |

| HF17-70A | 4mm | 70MPa | 2.2kg | Type C | Without | Light duty vehicles | HR1-70A |

| HF17-70AND | 4mm | 70MPa | 2.7kg | Type C | With | Light duty vehicles |

5. How to order:

With years of experience and extensive expertise in hydrogen fueling industry, we are prefessional for hydrogen refueling solutions. Please feel free to INQUIRE us. Customized hydrogen receptacles are on request.

★ For more details, please download ![]() HF17-70AND Hydrogen Fueling Nozzle Selection Guide

HF17-70AND Hydrogen Fueling Nozzle Selection Guide