● High payload up to 630kg;

● 5 postions for mounting modules, no pneumatic ports;

● For sorting, transporting, assembling, grinding, welding and deburring etc.;

● With self-locking funtion to prevent master plate and tool plate from being seperated due to accidential cut-off of air supply ;

● Monitoring master side with the proximity sensor at real time.

LANGAN® EOAT Modular Robotic Tool Changer provides a strong and reliable support for the seamless switching or changing between different toolings, which significantly reduces downtime and increases overall throughput as well as safety.

We, as a Robotic Tool Changer manufacturer, keep working to meet the soaring demand for robots for various industrial applications. LANGAN® LA-RTC630 Automatic Robotic Tool Changer (ATC) with payload to 630kg provides end-of-arm tooling solutions, flexibility and efficiency.

1. Technical data

| Product name | LANGAN® LA-RTC630 robotic tool changer with heavier load to 630kg | ||

| Main body | Rated payload | 630kg | |

| Static moment (X&Y) | 5000N.m | ||

| Static torque (Z) | 5000N.m | ||

| Locking force | 20000N | ||

| Housing size (when locked) |

Φ200mm×100mm

|

||

| Positioning repeatibility accuracy (X, Y&Z) | ±0.02mm | ||

| Weight | Master plate | 6200g | |

| Tool plate | 3200g | ||

| Material | Main body | Aluminium alloy | |

| Locking unit | Steel alloy | ||

| Locking unit | Ball locking | ||

| Pilot pressure | 0.4-0.7MPa | ||

| Pneumatic port | No pneumatic ports | ||

| Pilot air inlet | G1/8 | ||

Note: Customized version available on request for special working conditions.

2. Features:

● Payload up to 630kg;

● Main body has 5 positions for mounting modules, but no pneumatic ports;

● For sorting, transporting, assembling, grinding, welding and deburring etc.;

● With self-locking function to prevent master plate and tool plate from being separated due to accidential cut-off of air supply;

● Monitoring master side with the proximity sensor at real time.

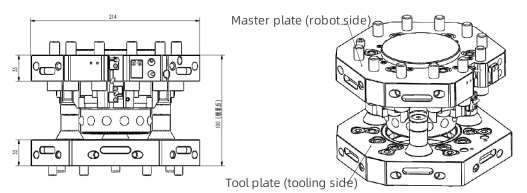

3. Dimensional drawings of LA-RTC630 Automatic Heavy-Duty Robot Tool Changer:

A Robot Tool Changer consists of a master plate and a tool plate, which are designed to lock together automatically. The Master plate of the Tool Changer mounts to a robot. The tool plate of the Tool Changer mounts to toolings of grippers, welders, or deburring tools etc.

The robot tool changer allows the robot to switch from one utility to another quickly, accurately and efficiently.

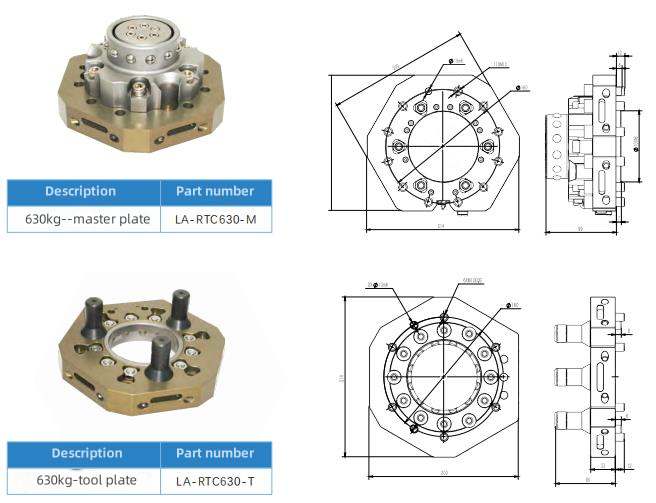

4. Mounting hole diagrams of LA-RTC630 Robot Tool Changer:

5. Optional modules:

● Control and signal modules

|

Master plate | LA-D009M | 23-core, 6A AC/DC 30V |

| Tool plate | LA-D009T | ||

|

Master plate | LA-D010M | 92-core, 6A AC/DC 30V |

| Tool plate | LA-D010T |

● Pneumatic and fluid modules

|

Master plate | LA-Y002M |

▪ 1 circuit, Rc1/2; ▪ nominal bore:12mm |

| Tool plate | LA-Y002T | ||

|

Master plate | LA-Y003M |

▪ 4 circuits, Rc1/2; ▪ nominal bore:12mm |

| Tool plate | LA-Y003T |

● Pneumatic modules

|

|

Master plate | LA-Q104M |

▪ 1 circuit, Rc1/2; ▪ Nominal bore:11mm ▪ Connection with thread ▪ With single or no valve |

| Tool plate | LA-Q104T | ||

|

Master plate | LA-Q105M |

▪ 2 circuits, Rc3/8; ▪ Nominal bore: 6mm ▪ Connection with thread ▪ With single or no valve |

| Tool plate | LA-Q105T |

● Welding modules

|

Master plate | LA-H101M |

▪ 1000V/150A ▪ 2-phase, grounded |

| Tool plate | LA-H101T |

● Safety modules

|

Master plate | LA-ARTC630M |

▪ G1/8; ▪ Connection with thread |

| Tool plate | LA-ARTC630T |

● Hydraulic modules

|

Master plate | LA-Y801M |

▪ 2 circuits; ▪ Nominal bore: 8mm; ▪ Max. pressure: 250bar |

| Tool plate | LA-Y801T |

● Shielded and grounded modules

|

Master plate | LA-J001M | Max. current: 70A |

| Tool plate | LA-J001T |

6. Teaching Aid:

|

Description | Part number |

| LA-RTC630 Teaching aid | LA-SRTC630 |

7. Working environmental conditions:

• Ambient temperature: 0℃ ~ 60 ℃ • Humidity: 0~95%

Robotic tool changers should be able to operate within a specific temperature range to ensure optimal performance and lifespan. It is advisable to consider the environmental conditions of your automation system and select a tool changer that can withstand these conditions.

Note: Please indicate to us when ordering if substances, such as dust, iron dust and acid gas etc, are present in the working environment.

8. Ordering:

As a manufacturer of Robotic Tool Changers, LANGAN® Automatic Robot Tool Changer models cover an extensive range of applications, from very small payloads 10kg to heavy payload 630kg. Custom-tailored robot tool changer models are available on request.

If you are interested in our Robot Tool Changer, Please feel free to inquire us.